Knowledge of a wide range of industries

OUR CABLE BLOG

Core Production Processes of a Cable Manufacturing Plant

Cable manufacturing is a meticulous process requiring high precision and advanced technology. This article delves into the core production processes that define the efficiency and quality of a cable factory.

1. Wire Drawing

The process begins with wire drawing, where raw materials such as copper or aluminum are pulled through a series of dies to reduce their diameter and achieve the desired thickness. This stage is critical to ensuring electrical conductivity and mechanical strength.

2. Insulation Extrusion

After drawing, the wires undergo an insulation extrusion process. Insulating materials, such as polyethylene or PVC, are melted and uniformly coated around the conductors. This step ensures electrical isolation and protection against environmental factors.

3. Stranding and Twisting

In this stage, individual wires are twisted together to form a stranded conductor. Stranding improves flexibility and enhances the durability of the cable, making it suitable for various applications.

4. Shielding and Wrapping

To protect against electromagnetic interference, shielding materials like aluminum foil or braided copper are applied around the cable core. Wrapping layers are also added for additional mechanical protection.

5. Jacketing

The final step is the application of an outer jacket. Using materials such as PVC, rubber, or low-smoke zero-halogen (LSZH) compounds, this layer provides mechanical strength, weather resistance, and fire safety.

6. Quality Testing

Throughout these stages, rigorous quality tests are conducted. This includes electrical performance tests, mechanical stress evaluations, and environmental durability assessments to meet industry standards.

By mastering these core processes, cable manufacturers can produce high-quality products that meet diverse industry requirements. From household wiring to high-voltage power transmission, these cables form the backbone of modern infrastructure.

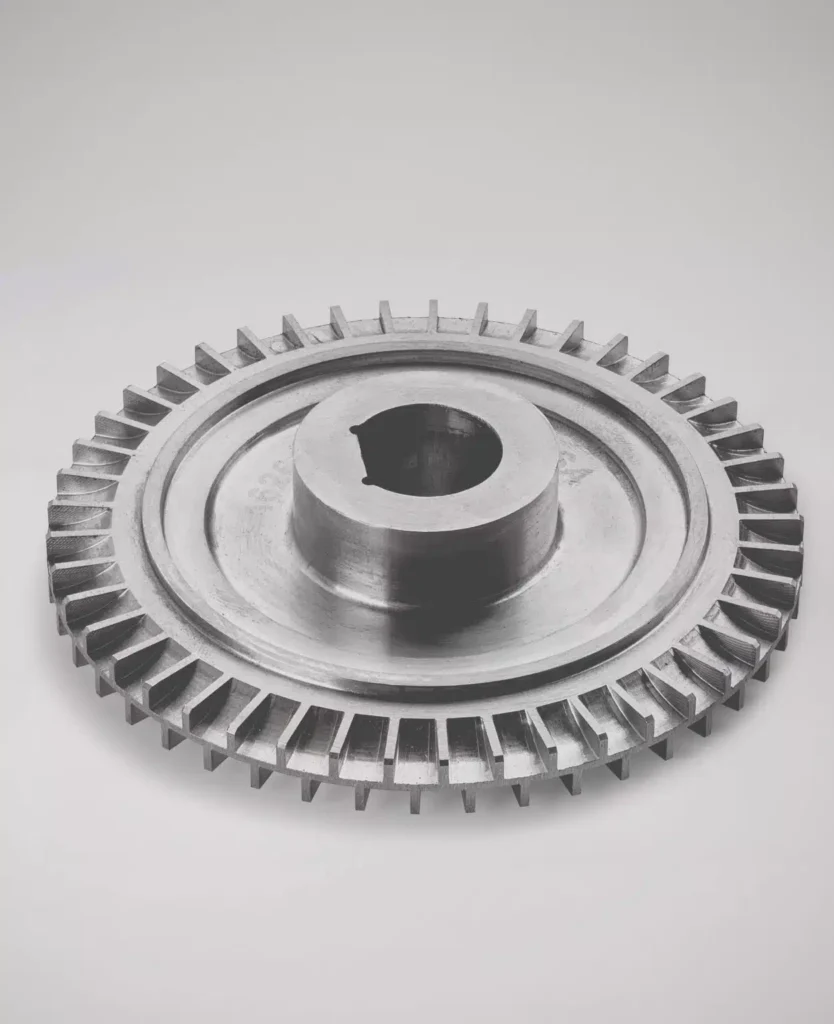

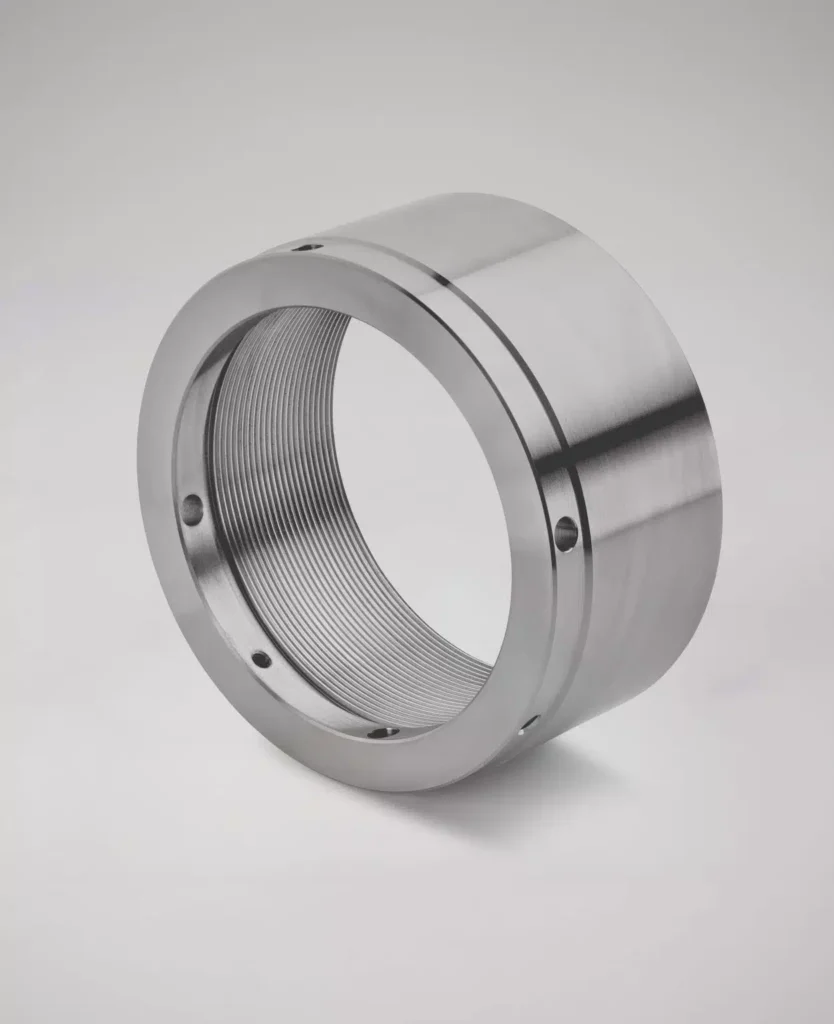

MASTERING THE ART OF SHAFTS

Custom Manufactured Shafts

We proudly manufacture shafts and components used to efficiently transfer energy from one part of a machine to another. From marine submersibles to pumps and electric motors—our shafts are custom manufactured with ultra-minute grinding tolerances for a product that fits YOUR application and functions properly. At Empower, we grind so that whatever you build keeps moving forward.

Ready to Collaborate?

Reach Out Today!

Navigation

- support@ewermfg.com

- (937) 365-7420

- 3249 Dryden Road Moraine, OH 45439

- 3660 Benner Rd, Miamisburg, OH 45342